Product categories

- Anchor Bolt

- Bolt

- DIN 1481

- DIN 444 Eye Bolt

- DIN 603 Carriage Bolt

- DIN 6921 FLANGE BOLT

- DIN 7984 Hex Socket Head Cap BoIt with Low Head

- DIN 91 3/91 4/9151916 Set Bolt

- DIN 912 Hex Socket Head Cap Bolt

- DIN 913/931 Hex Bolt

- DIN 933/931 HEX BOLT

- DlN 6921 Flange Bolt

- DlN 7991 Hex Socket Countersunk Head Cap Bolt

- ISO 7380 Hex Socket Button Head bolt

- T-bolt

- U-bolt

- welding Bolt

- Hexagon socket bolts

- Nut

- Other

- Screw

- Threaded Rod & Studs

- Washer

Products

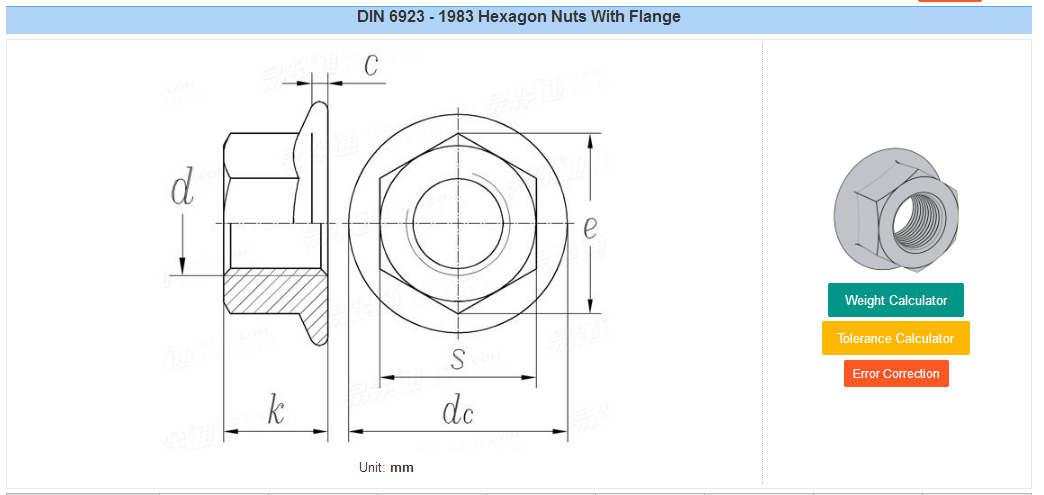

Stainless Steel DIN 6923 Flange Nut

Min.Order Quantity:1000PCS

PACKAGING:BAG/BOX WITH PALLET

PORT:TIANJIN/QINGDAO/SHANGHAI/NINGBO

DELIVERY:5-30DAYS ON QTY

PAYMENT:T/T/LC

Supply Ability:500 TON PER MONTH

- FOB Price:US $0.5 – 9,999 / Piece

- Min.Order Quantity:100 Piece/Pieces

- Supply Ability:10000 Piece/Pieces per Month

Description

| Product name | A2-70 Flange Nut |

| Size | M5-20 |

| Grade | SS304/SS316 |

| Material | Carbon steel |

| Surface treatment | Plain |

| Standard | DIN/ISO |

| Certificate | ISO 9001 |

| Sample | Free Samples |

Usage:

The flange nut is mainly used to increase the contact surface with the work piece. It is mostly used in pipelines, and the fasteners have been stamped and stamped.

Flange nuts and general hex nuts are basically the same size as the thread specifications, but compared to hex nuts, it is a one-piece gasket and nut, and has non-slip tooth patterns underneath, which increases the nut and the workpiece The surface area contact is stronger and stronger than the combination of ordinary nut and washer.

The common flange nut specifications are generally below M20, because most flange nuts are used in pipes and flanges.

Common questions about stainless steel:

Q: Why is stainless steel magnetic?

A: 304 stainless steel belongs to austenitic stainless steel. Austenite is partially or slightly transformed into martensite during cold working. Martensite is magnetic, so stainless steel is nonmagnetic or weakly magnetic.

Q: How to identify authentic stainless steel products?

A: 1. Support stainless steel special potion test, if it does not change color, it is authentic stainless steel.

2.Support chemical composition analysis and spectral analysis.

3. Support smoke test to simulate the actual use environment.

Q: What are the most commonly used stainless steels?

A: 1.SS201, suitable for use in dry environment, easy to rust in water.

2.SS304, outdoor or humid environment, strong resistance to corrosion and acid.

3.SS316, molybdenum added, more corrosion resistance, especially suitable for seawater and chemical media.

Five advantages of stainless steel:

1. High hardness, no deformation —– The hardness of stainless steel is more than 2 times higher than that of copper, more than 10 times higher than that of aluminum, the processing is difficult, and the production process is complicated.

2.Durable and non-rusty —- made of stainless steel, the combination of chrome and nickel creates a layer of anti-oxidation on the surface of the material, which plays the role of rust.

3.Environmentally friendly, non-toxic and non-polluting ——- Stainless steel material has been recognized as sanitary, safe, non-toxic and resistant to acids and alkalis. It is not released to the sea and does not pollute tap water.

4. Beautiful, high-grade, practical ——– Stainless steel products are popular all over the world. The surface is silver and white. After ten years of use, it will never rust. As long as you wipe it with clean water, it will be clean and beautiful, as bright as new.

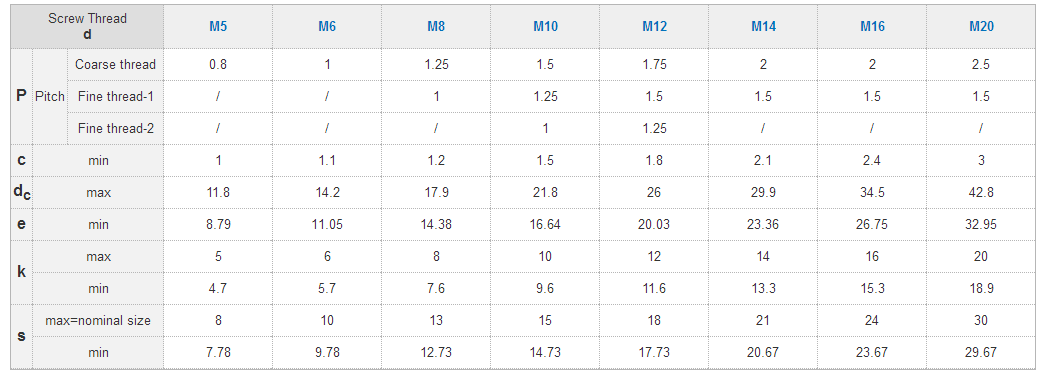

Parameter Of Product: